Offset, foil-stamped, letterpress, engraving… if you want awesome printed invitations but this is all gibberish to you, this is the wedding invitation printing techniques primer you need. We're going to break down all your options including the ones we just mentioned AND some economical and eco-friendly invitation alternatives. Let's talk shop about printing.

Offset printing and thermography

Price: $

The least expensive technique involves a high-speed offset press that transfers the ink onto paper. It prints a single color at a time, layering each color on top of the other to produce the design. This technique is easily found online at places like Vistaprint or your local print shop.

The text can be left flat as with normal offset printing or thermographed for a raised effect using a powdered resin. This can mimic an expensive engraved look, which we'll talk about later.

Digital printing

Price: $

Digital printing, espcially in small batches, can be very economical. While the actual digital printing has a higher cost per page than offset printing, there is an offsetting cost savings because there is no need to make printing plates. Digital printing can also be turned around really quickly if you're in a hurry. The trade-off is that a lot of printers aren't able to digitally print on thicker paper stock, so you may be relegated back to offset if you want a thicker invitation.

Foil stamping

Price: $$ – $$$

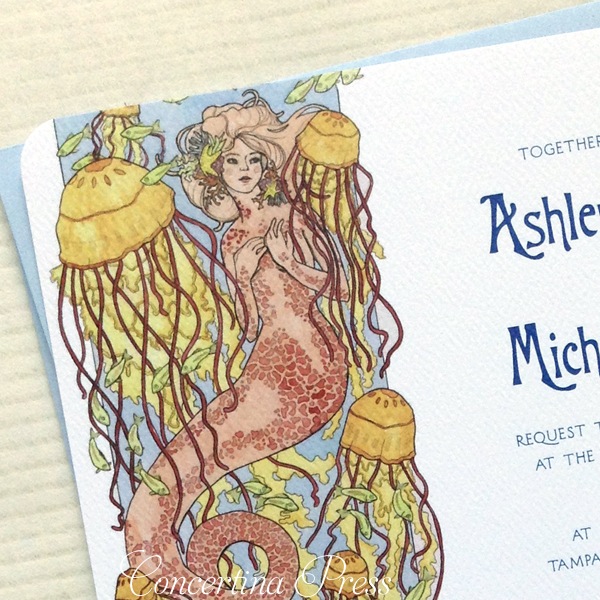

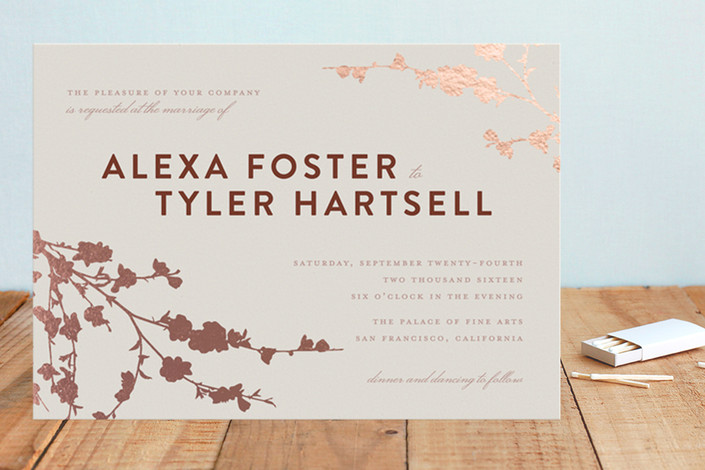

Things start to get fancier from this point on. In foil stamping, the design of your wedding invitation is etched into a copper plate, and then foil (either metallic or otherwise) is heated and applied to the paper with pressure. This can be especially dramatic with light-colored foil on a dark background. Depending on the design, foil stamping can sometimes get a little pricey. If you choose this route, check about turnaround times since this technique is sometimes outsourced, adding to the time needed to produce them.

Letterpress

Price Level: $$$

Letterpress is similar to foil stamping, except it's pressing ink into the paper instead, leaving the letters indented on the front and raised on the back of the invite. Letterpress mostly requires a thicker, bulkier paper like cotton fiber, which allows for the best visbility. To save some cash, limit your ink colors.

Engraving

Price Level: $$$$

Engraving is the granddaddy of printing techniques and the price reflects that. The lettering is raised on the front and indented on the back, and the paper and ink requirements allow you a lot of flexibility in color (like brilliant light-colored ink on dark paper). It requires a heavy-duty cardstock due to the intense pressure of the printing process. Engraving without ink is called embossing, which will give you a colorless stamped look.

More finishes and final touches

Invitations can be mounted on stiffer paper for extra thickness and edges can be trimmed to a bevel, painted, or foiled to add another element to the design.

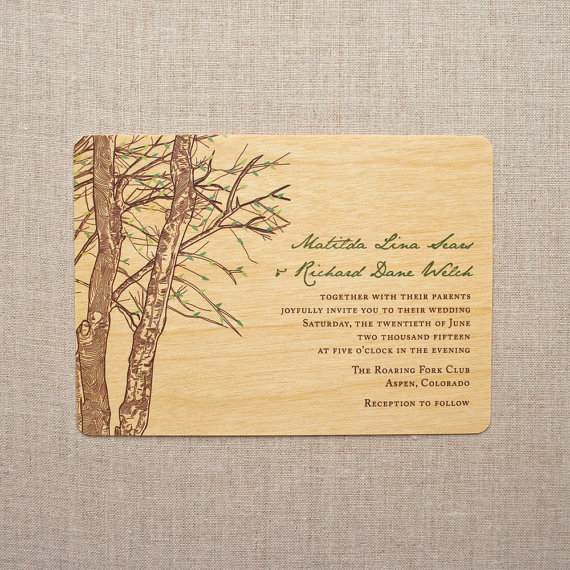

Alternately, you can look into die-cut invitations or even engraved on metal or wood.

Email invitations and other economical options

Want to pack in the concept of printed invitations altogether and go digital? Here are some of our favorite resources for emailed invitations and download and print-style.

Email invitation resources

Print-it-yourself resources

Have you decided if you'll be sending printed invitations? Formal letterpress gorgeousness, funky email invites, Sharpied flip-flops? Tell us about it in the comments!

Nice collection i love the way it represent the print on that it’s look Awesome…

All the collection is just superb..specially Engraving i just love this…

Thanks for share such a lovely post….

I’d say that the pricing for letterpress printing is off. Especially now with all the smaller presses popping up, you’re not limited to the big name presses, and this competition has helped bring down the price of letterpress printing (as has photopolymer plates). Letterpress is typically less expensive than hot foil-stamping, because hot-foil can only be done with custom etched metal dies, which are much more expensive to make than the photopolymer plates that most letterpress printers now use. The machinery and type of paper used in both is basically identical.